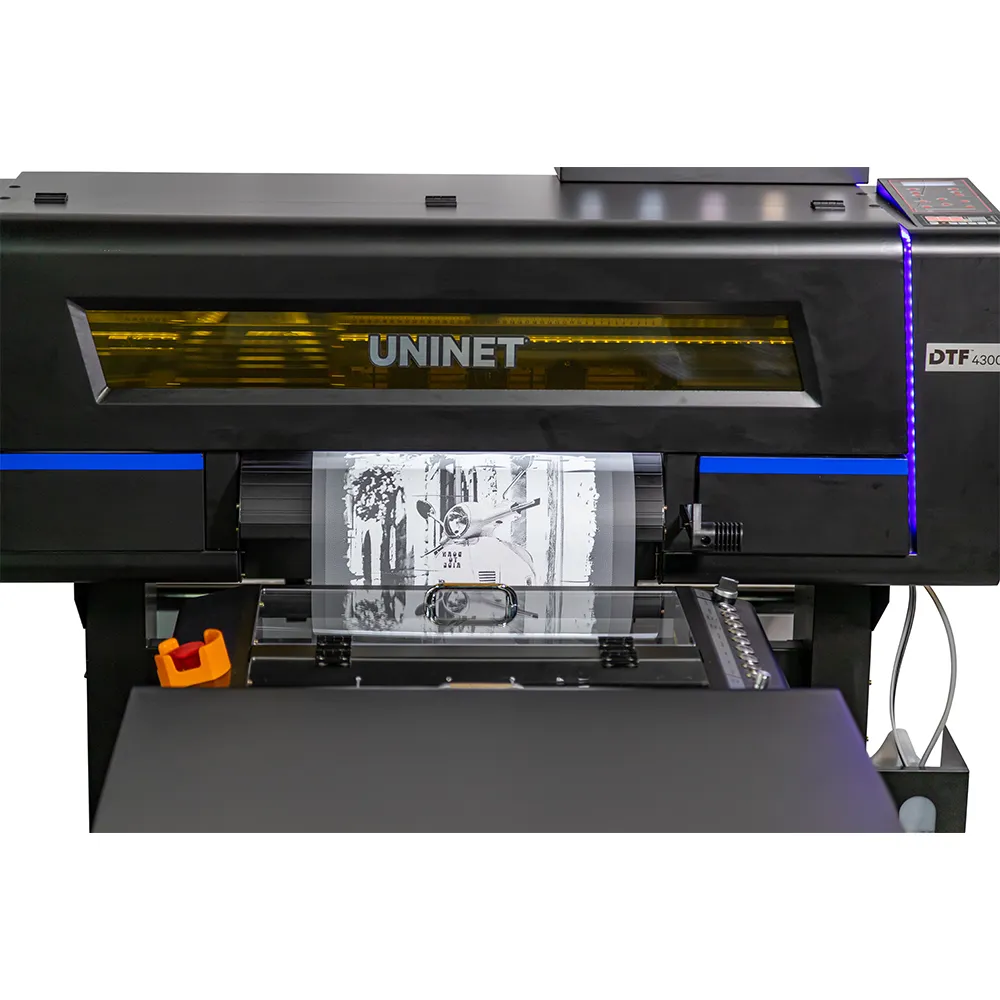

The UNINET DTF 4300 elevates the garment industry with its cutting-edge, high-performance technology for medium to large-scale industrial use. Upgraded with an expansive 17 inch wide roll feed system, the printing capability allows for a wider array of garment and accessory applications. Let your creativity run free and allow for the most stunning quality and customized apparel to impress your customers.

Whether you are creating simple and detailed designs or elaborate colorful masterpieces, the UNINET 4300 allows for a dazzling alternative to other applications that take time to weed and apply. The ability to apply to dark or light colors and a massive array of fabrics, cotton, polyester, leather, canvas, spandex, linen, and so much more makes the UniNET 4300 DTF printer a solid option for any thriving garment business that is looking for high-productivity.

Boasting its industrial-grade dual print head design and tiny dot gain, The UNINET DTF 4300 printing system can produce high-definition prints and excellent color fidelity. Using a combination of five inks, which considerably increases the number of colors conceivable, this technology uses an automated process to lay down layers of CMYK colors and print white as overprint, all in a single pass, resulting in professional, unrivaled print quality and sharpness.

The UNINET DTF 4300 is not just a printer! It's a complete DTF startup solution that includes ProRIP advanced RIP software, 2-hr virtual onboarding, five-color 1000 ml bottles, transfer powder, DTF film roll, and a 12-month warranty.

Features:

- Accepts DTF rolls up to 17 inches wide

- Vacuum-enhanced printing area for better ink adhesion and avoidance of film buckling

- WICS (White Ink Circulation System) to minimize clogging

- Two high-definition industrial-grade inkjet printheads

- Continuous XL ink take feed system

- Humidity sensor

- RIP and Roller software included

- Advanced bi-directional media roller system for easy and fast feed controls

- Setup assistance and Master Class training included

Please Note: This equipment requires a well-ventilated area with a filtration system. When working with DTF products and processes, use appropriate personal protective equipment since fumes might be harmful. DTF inks and film/sheets need an adequate humidity environment - above 50% humidity is strongly advised to reduce the possibility of ink clogs and film buckling.

Cart(

Cart(