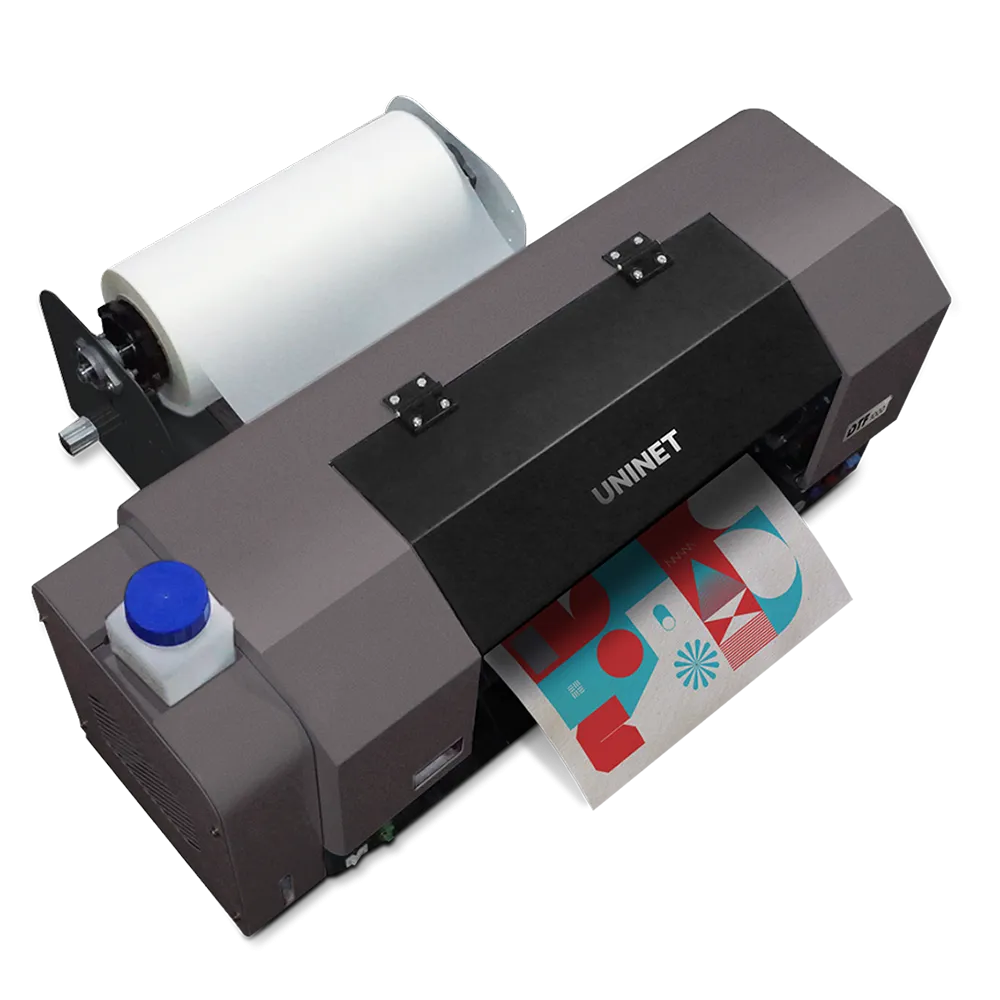

The UNINET DTF 1000 is a roll-fed 13-inch desktop DTF (Direct to Film) solution. It is built to perform for the short-volume production of exceptional quality, full-color print transfers for the digital apparel decorating market, which can be applied to light and dark-colored garments.

The DTF1000 is compact yet powerful, expertly configured for manual DTF powder application, and is capable of producing simple or intricate, colorful weedless digital transfers in a single pass. As an optional upgrade, the DTF™ 1000 can be paired with the *UNINET® DTF™ 1000 Auto-Powder Unit to enable fully automated powder application, curing, and drying for a comprehensive, high-volume printing solution.

The UNINET DTF 1000 is not just a printer! It's a complete DTF startup solution that comes with ProRIP software, ink bottles, PET film, transfer powder, supplies, setup assistance, and training.

Features:

- Roll-fed printer maximizes efficiency, 13-inch film supports pro-size transfers.

- Vacuum-enhanced printing area for better ink adhesion and avoidance of film buckling

- High-resolution photo-quality prints from advanced 1440dpi piezo print head

- Print speeds up to 13 square ft/hr.

- Six-channel piezo print engine supports CMYK plus white

- Automated WICS (White Ink Circulation System)

- Conveniently located front control panel

- XL White Ink Tank and Advanced Continuous Feed System

- DTF specialized Damper system for improved pressurized delivery of ink

- Humidity Sensor

- RIP and Roller Software Included

- Advanced bi-directional media roller system for easy and fast feed controls

- Setup assistance and Master Class training included

Please Note: This equipment requires a well-ventilated area with a filtration system. When working with DTF products and processes, use appropriate personal protective equipment since fumes might be harmful. DTF inks and film/sheets need an adequate humidity environment - above 50% humidity is strongly advised to reduce the possibility of ink clogs and film buckling.

Cart(

Cart(